Surgical instruments are the backbone of modern medical procedures, enabling doctors to perform life-saving surgeries with precision and accuracy. From general surgery instruments to specialized surgical tools, these instruments have transformed healthcare by improving the efficiency, safety, and outcomes of surgical operations.

In this comprehensive article, we will dive into the world of surgical instruments, discussing the importance of high-quality tools, exploring surgical instrument manufacturers, and highlighting the role of stainless steel surgical instruments in ensuring durability and precision.

What Are Surgical Instruments?

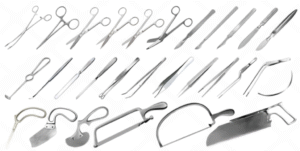

Surgical instruments refer to tools specifically designed for medical procedures that involve the cutting, manipulation, or repair of tissue. These instruments vary widely, from basic scalpels to complex equipment used in specialized surgeries. Depending on the type of surgery, instruments are classified into cutting, grasping, clamping, and suturing tools.

Types of Surgical Instruments Used in General Surgery

General surgery is one of the most common branches of surgery, dealing with various procedures such as appendectomies, hernia repairs, and gallbladder removals. The instruments used in general surgery vary but typically include:

- Scalpels and Blades: Essential for making precise incisions.

- Forceps: Used for grasping tissue or organs.

- Scissors: Vital for cutting tissues, sutures, or blood vessels.

- Needles and Needle Holders: For stitching tissues back together.

- Clamps and Hemostats: Used to control bleeding during surgery.

Each of these tools must meet rigorous standards of quality and safety, ensuring they perform efficiently during critical procedures.

The Role of Surgical Instruments Companies in Modern Healthcare

Surgical instruments companies are the backbone of the medical equipment industry, responsible for the design, manufacturing, and distribution of surgical tools. These companies work in close collaboration with healthcare professionals, ensuring that each instrument meets the specific needs of different surgeries.

Surgical Instruments Suppliers and Manufacturers

A surgical instruments company plays a crucial role in supplying hospitals, clinics, and surgical centers with the essential tools they need. Some well-established companies specialize in manufacturing high-quality instruments that cater to a wide variety of surgeries, such as:

- General Surgery Instruments

- Orthopedic Instruments

- Cardiovascular Instruments

- Neurosurgery Instruments

These manufacturers adhere to stringent industry standards to ensure their products are both durable and reliable, particularly concerning materials like stainless steel.

Stainless Steel Surgical Instruments: Durability and Precision

Stainless steel is the preferred material for most surgical instruments, and for good reason. It offers the perfect combination of strength, durability, and resistance to corrosion, making it ideal for medical use. Stainless steel surgical instruments maintain their sharpness longer, ensuring precise and safe surgeries. Furthermore, the non-reactive properties of stainless steel ensure that the instruments can be sterilized effectively without compromising their quality.

Advantages of Stainless Steel Surgical Tools

- Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, crucial in surgical environments where cleanliness is essential.

- Strength and Durability: Stainless steel instruments can withstand high levels of stress and strain without breaking or warping.

- Easy Sterilization: Stainless steel is ideal for sterilization, ensuring that surgical instruments remain hygienic and safe to use across various procedures.

Key Surgical Instruments Made from Stainless Steel

- Scalpels: Sharp, durable blades used for making precise cuts.

- Surgical Forceps: Grasping tools used in delicate tissue handling.

- Needle Holders: Used to hold needles during suturing.

- Scissors: Cutting tools with specialized blades for different surgical needs.

Top Surgical Instruments Manufacturers

There are many manufacturers around the world that specialize in creating high-quality surgical tools. Some of the top surgical instruments manufacturers include:

- Medtronic: A global leader in medical devices, offering a wide range of surgical instruments.

- Stryker: Known for providing high-performance surgical tools for various specialties, including orthopedics and neurosurgery.

- Johnson & Johnson: A well-established name in healthcare, offering surgical instruments and medical devices for numerous procedures.

- B. Braun: Specializes in surgical instruments for general, urological, and orthopedic surgeries.

These companies have built a reputation for producing instruments that meet the highest standards of quality and performance.

Surgical Tools Manufacturers and Their Quality Assurance

Manufacturers of surgical instruments must meet strict regulatory requirements set by global organizations such as the FDA (Food and Drug Administration) in the U.S. and CE (Conformité Européene) in Europe. These certifications ensure that the tools are safe and effective for use in medical procedures.

Key Quality Standards in Surgical Instruments Manufacturing

- ISO 13485 Certification: This standard ensures that the manufacturer has a consistent and effective quality management system.

- FDA Approval: In the United States, surgical instruments must pass FDA scrutiny to be sold.

- CE Marking: Surgical instruments must meet the safety and performance requirements outlined by the European Union to earn this certification.

By adhering to these standards, surgical instrument companies guarantee their products’ reliability in critical surgical settings.

The Evolution of Surgical Instruments: From Basic Tools to Modern Marvels

Surgical tools have evolved significantly over the centuries. From rudimentary blades and hooks used in ancient civilizations to today’s highly specialized tools made with cutting-edge technology, the progress in surgical instruments has been remarkable. Key milestones include:

- Ancient Surgical Instruments: Early tools made from stone, bone, and metals like bronze were used for basic surgeries.

- Industrial Revolution: The 19th century brought the mass production of steel instruments, making them more durable and affordable.

- Modern Surgical Tools: Today, high-tech instruments include robotic surgery tools, lasers, and minimally invasive instruments that allow for quicker recoveries.

Real-Life Examples of Surgical Instruments in Use

Case Study 1: The Role of Surgical Instruments in Minimally Invasive Surgery

Minimally invasive surgery (MIS) has revolutionized the field of surgery. Instruments like laparoscopes, endoscopes, and robotic arms have allowed surgeons to perform complex procedures with smaller incisions, resulting in shorter recovery times and less pain for patients.

Case Study 2: The Impact of Stainless Steel in Cardiac Surgery

In cardiac surgery, where precision and reliability are paramount, stainless steel instruments are essential. From coronary artery bypass grafting (CABG) to valve replacements, these instruments ensure that delicate procedures are carried out safely and effectively.

Explore more latest details about how to Make Moving Stress-Free

Pros and Cons of Surgical Instruments

Pros

- Precision and Accuracy: High-quality surgical instruments, particularly those made from stainless steel, allow for accurate, clean cuts and sutures.

- Durability: Instruments made from stainless steel are durable and resistant to wear and tear.

- Sterilization: Surgical instruments made of stainless steel are easy to sterilize, ensuring a high level of hygiene during surgeries.

Cons

- Cost: High-quality surgical instruments can be expensive, especially when purchasing from top manufacturers.

- Maintenance: Even durable stainless steel instruments require regular maintenance to ensure they stay sharp and functional.

Frequently Asked Questions (FAQs)

- What are surgical instruments made of?

Surgical instruments are typically made of high-grade stainless steel due to its strength, durability, and corrosion resistance. - Why is stainless steel preferred for surgical instruments?

Stainless steel offers strength, resistance to corrosion, and ease of sterilization, making it ideal for use in surgical procedures. - How are surgical instruments sterilized?

Surgical instruments are sterilized using autoclaves, which use high-pressure steam to kill bacteria and other microorganisms. - Can surgical instruments be reused?

Yes, surgical instruments can be reused, provided they are properly sterilized between uses to ensure they are safe. - How do I choose the right surgical instruments supplier?

Look for suppliers with certifications like ISO 13485, FDA approval, and CE marking, which guarantee the quality and safety of their products. - What are some common surgical instruments used in general surgery?

Common instruments include scalpels, forceps, scissors, needle holders, and clamps.

Conclusion: The Importance of High-Quality Surgical Instruments

Surgical instruments are essential tools in the medical field, playing a crucial role in ensuring the success of surgeries. By partnering with reliable surgical instruments companies, hospitals and clinics ensure they have access to high-quality, durable tools that meet strict safety standards. Stainless steel surgical instruments, in particular, offer unmatched durability and precision, making them a staple in operating rooms worldwide.

As the medical field continues to evolve, so too will surgical tools, offering even more advanced solutions for surgeons and better outcomes for patients. If you’re interested in exploring more about surgical instruments or want to connect with a trusted supplier, don’t hesitate to reach out today!

Call to Action: Have you used surgical instruments in a medical setting? Share your experiences in the comments below, and feel free to ask any further questions about surgical tools! If you’re looking for high-quality surgical instruments, check out top manufacturers and suppliers for more information.