Roofing is a critical part of any building project, and achieving a durable, long-lasting roof requires both skill and the right tools. In recent years, roofing machines have revolutionized the construction industry by improving efficiency, reducing labor costs, and enhancing the overall quality of roof installations. These machines are designed to streamline tasks such as cutting, bending, shaping, and installing roofing materials, allowing contractors to complete projects faster and with greater precision.

Types of Roofing Machines

There are several types of roofing machines, each designed for a specific purpose. Choosing the right machine depends on the type of roofing material, project scale, and desired outcome.

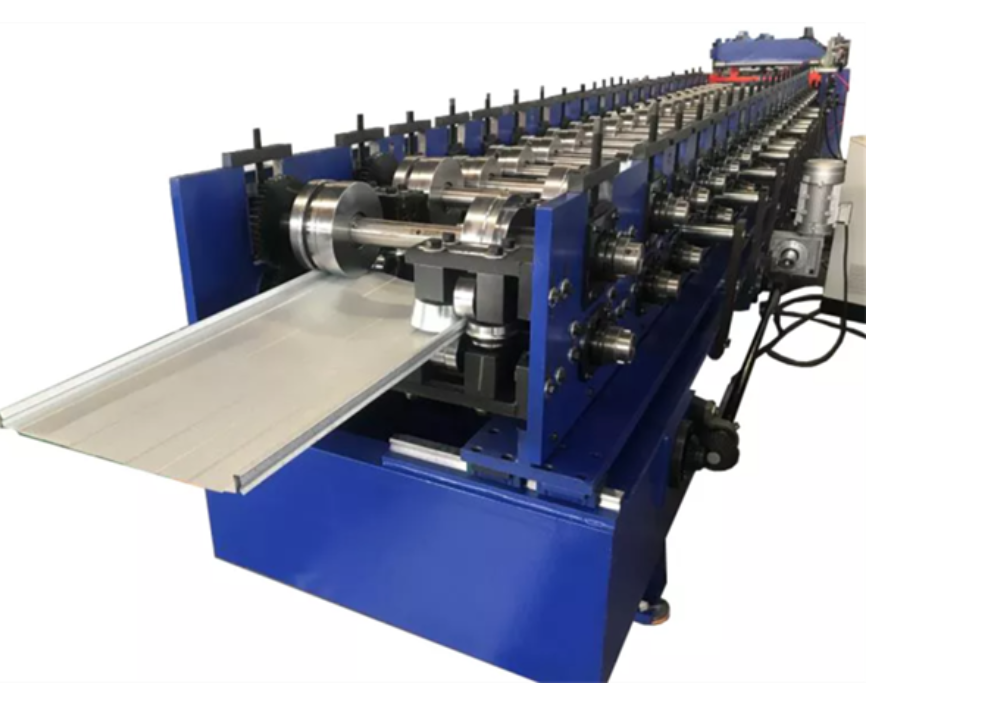

1. Roll Forming Machines

Roll forming machines are used to create continuous metal panels for roofs. They feed metal coils through a series of rollers that bend and shape the material into panels of the desired profile.

Benefits:

- Produces uniform, precise panels

- Reduces material waste

- Speeds up large-scale roofing projects

2. Seamers

Seamers are essential for installing standing seam metal roofs. They join adjacent panels securely, creating a weather-tight seal without the need for exposed fasteners.

Benefits:

- Ensures leak-proof seams

- Reduces the risk of panel damage

- Provides a professional, clean finish

3. Gutter Machines

Gutter machines are used to fabricate custom gutters on-site, matching the exact dimensions of the building. They streamline the gutter installation process and reduce errors.

Benefits:

- Customizable lengths and profiles

- Fast and efficient fabrication

- Minimizes material wastage

4. Cutting and Notching Machines

These machines are designed to cut roofing materials, including metal sheets and shingles, to precise dimensions. Notching machines create clean edges and allow panels to fit perfectly around corners, vents, and chimneys.

Benefits:

- Precise cuts for a professional finish

- Reduces manual labor and errors

- Compatible with a variety of materials

5. Roofing Rollers and Press Machines

Rollers and press machines are used to secure roofing membranes, asphalt sheets, and other flat roofing materials. They ensure proper adhesion and reduce the risk of air pockets or uneven surfaces.

Benefits:

- Guarantees smooth, uniform installation

- Reduces the likelihood of leaks

- Speeds up the installation process

Benefits of Using Roofing Machines

Enhanced Efficiency

One of the most significant advantages of roofing machines is the time they save. Tasks that once took hours of manual labor can now be completed in a fraction of the time. This efficiency is especially valuable for large commercial projects or when deadlines are tight.

Improved Precision and Quality

Manual installation can lead to inconsistencies, uneven seams, or improperly cut panels. Roofing machines ensure precise measurements, accurate cuts, and uniform installation, resulting in a high-quality roof that meets professional standards.

Reduced Labor Costs

By automating repetitive tasks such as cutting, forming, and seaming, roofing machines reduce the need for extensive manual labor. This not only lowers labor costs but also minimizes fatigue and errors among workers.

Consistency Across Projects

For contractors handling multiple projects, consistency is crucial. Roofing machines produce uniform results, ensuring that every roof meets the same high standards, regardless of size or complexity.

Safety Improvements

Roofing is inherently risky work. Machines reduce the need for workers to handle heavy panels or perform repetitive motions at heights, lowering the risk of accidents and injuries.

Applications of Roofing Machines

Residential Construction

Homebuilders and roofing contractors use roofing machines to install metal roofs, shingles, and gutters efficiently. These machines help achieve a polished, professional appearance while saving time and resources.

Commercial and Industrial Buildings

Large-scale projects, such as warehouses, factories, and office buildings, benefit significantly from roll forming machines and seamers. These tools allow contractors to handle extensive roof areas with minimal errors.

Custom Roofing Projects

For unique architectural designs or specialized roofing requirements, roofing machines provide flexibility and precision. Custom-shaped panels, gutters, and fittings can be produced on-site to match specific project needs.

Key Considerations When Using Roofing Machines

Machine Selection

Selecting the right roofing machine depends on the type of material and project requirements. For instance, standing seam metal roofs require specialized seamers, while roll forming machines are ideal for large-scale metal panel production.

Maintenance and Care

Proper maintenance is crucial for ensuring the longevity and performance of roofing machines. Regular lubrication, cleaning, and inspections prevent breakdowns and maintain operational efficiency.

Training and Expertise

Operators should be trained to use roofing machines safely and effectively. Proper training reduces the risk of accidents and ensures that machines are used to their full potential.

Site Preparation

Before using roofing machines, it’s essential to prepare the site. Clear workspaces, secure scaffolding, and organized material storage help streamline operations and reduce delays.

Material Compatibility

Not all roofing machines are compatible with every material. Contractors should verify that the machine supports the specific metal, shingle, or membrane type used in the project.

Common Misconceptions About Roofing Machines

Only for Large Projects

While roofing machines are invaluable for commercial projects, they are also suitable for residential roofs. Many machines are compact and portable, making them ideal for smaller-scale installations.

Expensive Investment

Although the initial cost of roofing machines can be high, the time saved, labor costs reduced, and quality improvements make them a worthwhile long-term investment.

Difficult to Operate

Modern roofing machines are designed with user-friendly controls and safety features. With proper training, operators can quickly become proficient in their use.

Conclusion

Roofing machines have transformed the way contractors approach roof installation. From roll forming machines and seamers to cutting tools and rollers, these machines enhance efficiency, precision, and safety, delivering high-quality results in less time.