High-Quality Custom CNC Machining Solutions are designed to deliver precision, durability, and consistent performance for a wide range of manufacturing applications. By using advanced CNC milling and turning technologies, these solutions ensure tight tolerances and accurate results for complex and custom-designed parts. Skilled machinists and modern CAD/CAM systems work together to transform detailed designs into high-performance components with minimal error.

High-quality materials, strict inspection processes, and reliable production methods guarantee long-lasting and dependable parts. From rapid prototyping to full-scale production, custom CNC machining solutions provide flexibility, efficiency, and cost-effective results for industries that demand superior quality and precision.

Table of Contents

ToggleHigh-Quality Custom CNC Machining Solutions

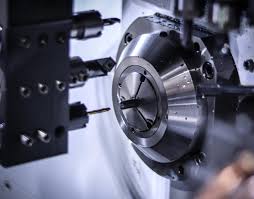

High-Quality Custom CNC Machining Solutions are designed to deliver precision, durability, and consistent performance for a wide range of manufacturing applications. In today’s competitive industrial environment, manufacturers require components that meet exact specifications while maintaining efficiency and reliability. Custom CNC machining fulfills these demands by using advanced computer-controlled equipment to produce accurate and repeatable parts. Whether the requirement is for simple components or complex geometries, CNC machining ensures tight tolerances and uniform quality across every production cycle.

By using advanced CNC milling and turning technologies, these solutions ensure accurate results for complex and custom-designed parts. Skilled machinists and modern CAD/CAM systems work together to transform detailed digital designs into high-performance components with minimal error. This integration of human expertise and automated technology allows manufacturers to achieve consistent results while reducing production risks and material waste.

High-quality materials, strict inspection processes, and reliable production methods guarantee long-lasting and dependable parts. From rapid prototyping to full-scale production, custom CNC machining solutions provide flexibility, efficiency, and cost-effective results for industries that demand superior quality and precision. These solutions play a vital role in helping businesses maintain product reliability, meet deadlines, and adapt to changing market demands.

Precision-Focused CNC Machining Excellence

High-Quality Custom CNC Machining Solutions are built around precision-focused manufacturing processes that deliver accurate and repeatable results. Precision is the foundation of CNC machining, enabling manufacturers to create components that meet exact dimensional and functional requirements. Advanced CNC milling and turning machines operate with exceptional accuracy, ensuring each part is produced according to design specifications without deviation.

Computer-controlled operations minimize human error and ensure consistency across every production run. This level of control is essential for businesses that require dependable performance, particularly in applications where even minor inaccuracies can lead to system failure. CNC machining supports tight tolerances and superior surface finishes, making it ideal for both standard and complex components.

Precision machining enhances product reliability, reduces material waste, and improves overall production efficiency. With modern technology and skilled operators, high-quality CNC machining ensures components meet demanding performance standards while maintaining cost-effectiveness. This precision-focused approach allows manufacturers to deliver components that integrate seamlessly into larger assemblies, improving overall system performance and longevity.

Advanced Technology for Superior Manufacturing Results

The use of advanced CNC technology plays a vital role in delivering high-quality custom machining solutions. Modern CAD and CAM software allows complex designs to be converted into precise machine instructions, ensuring flawless execution throughout the manufacturing process. These digital tools enable manufacturers to simulate production, identify potential issues, and optimize designs before machining begins.

Multi-axis machining capabilities enable the production of complex geometries that traditional manufacturing methods cannot achieve. Components with intricate angles, curves, and internal features can be produced accurately and efficiently using advanced CNC equipment. Automation improves production speed while maintaining consistent quality, making it possible to meet tight deadlines without compromising precision.

These technological advancements help manufacturers remain competitive by improving efficiency, accuracy, and scalability. By integrating cutting-edge equipment with intelligent software systems, custom CNC machining solutions provide superior manufacturing results that support innovation, reliability, and long-term production success.

Custom Machining Solutions for Diverse Industries

High-Quality Custom CNC Machining Solutions serve a wide range of industries, each with unique requirements and quality standards. Aerospace, automotive, medical, electronics, and industrial manufacturing sectors rely on CNC machining for dependable and precision-engineered components. Each industry demands strict compliance with performance, safety, and quality guidelines, which CNC machining consistently delivers.

Custom solutions allow manufacturers to adapt designs, materials, and production volumes to meet specific industry demands. CNC machining supports both rapid prototyping and large-scale production, enabling businesses to test designs, refine products, and scale operations efficiently. This flexibility reduces development time and accelerates time-to-market.

Whether producing prototypes or full-scale production parts, CNC machining offers flexibility and scalability. This adaptability ensures businesses receive components tailored to their applications, improving product performance and reducing development risks. Custom CNC machining continues to be a trusted solution across industries that demand accuracy, reliability, and long-term performance.

Material Quality and Strict Quality Control Standards

Material selection and quality control are critical aspects of high-quality custom CNC machining solutions. Precision components must perform reliably under real-world conditions, making material strength, durability, and consistency essential. CNC machining supports a wide range of metals and engineering plastics, including aluminum, steel, stainless steel, brass, titanium, and advanced polymers.

Strict inspection procedures, including dimensional checks and surface analysis, ensure every part meets defined specifications. Quality control processes are applied at every stage of production, from raw material selection to final inspection. Advanced measuring tools and inspection techniques help identify deviations early, reducing defects and ensuring consistent results.

By focusing on material integrity and quality assurance, custom CNC machining solutions deliver durable, high-performance parts that meet international manufacturing standards. These rigorous quality practices provide customers with confidence in the reliability and longevity of their components.

Reliable CNC Machining Solutions for Long-Term Value

Reliability and long-term value define high-quality custom CNC machining solutions. Businesses benefit from consistent production output, reduced rework, and dependable delivery schedules. CNC machining processes are designed to maintain repeatability, ensuring that every part meets the same high standards regardless of production volume.

CNC machining partners often collaborate closely with clients to optimize designs for manufacturability. This collaboration helps reduce costs, improve efficiency, and enhance overall product quality. The combination of skilled machinists, advanced equipment, and proven processes ensures long-lasting results that support sustainable manufacturing practices.

These solutions also help minimize waste and maximize productivity, contributing to cost-effective and environmentally responsible manufacturing. By choosing high-quality custom CNC machining, businesses gain a competitive advantage through precision parts that enhance product quality, customer satisfaction, and long-term business growth.

Final Thoughts

High-Quality Custom CNC Machining Solutions provide the precision, consistency, and reliability that modern industries demand. By combining advanced CNC technology with skilled expertise and strict quality control, these solutions deliver custom components that meet exact specifications and tight tolerances. Their flexibility supports a wide range of materials, designs, and production volumes, making them suitable for both prototyping and full-scale manufacturing.

With a strong focus on accuracy, efficiency, and long-term value, custom CNC machining helps businesses improve product performance, reduce production risks, and maintain a competitive edge in today’s manufacturing environment. Investing in high-quality CNC machining solutions ensures dependable results, sustainable growth, and long-term success in precision-driven industries.