Butterfly valves with pneumatic operation are essential parts of contemporary industrial fluid control systems. MNC VALVES, a top pneumatic powered butterfly valve manufacturer in Ahmedabad, India, provides a potent blend of precise engineering, durability, and application diversity in response to the rising demand for high-performance automation solutions.

What is a Pneumatic Operated Butterfly Valve?

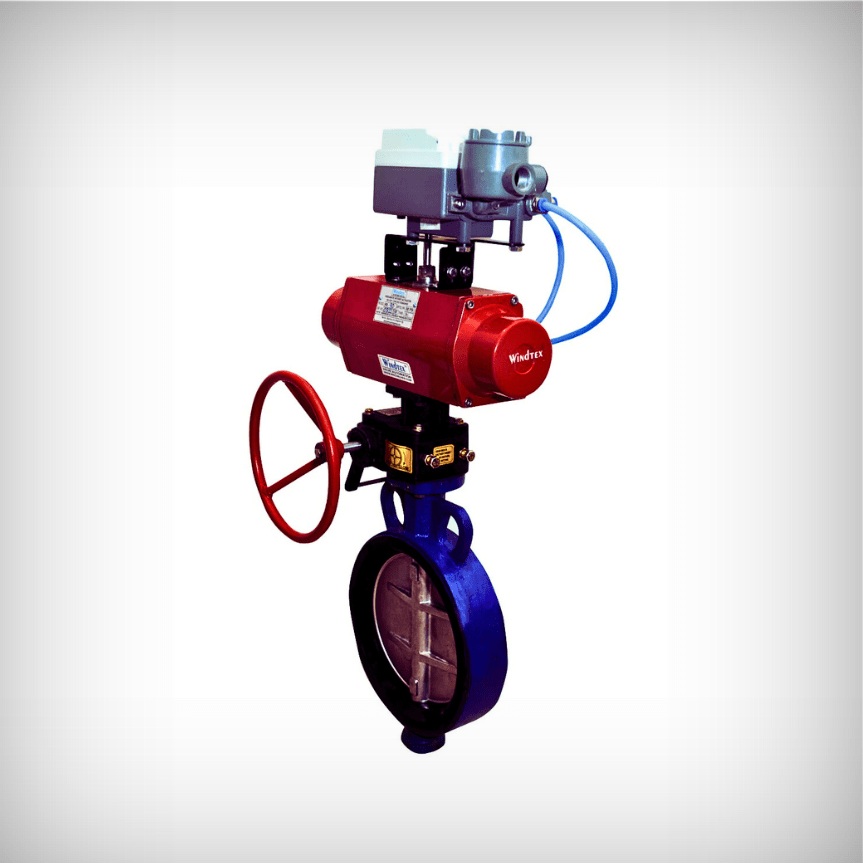

A pneumatic butterfly valve is a kind of flow control valve that opens or closes a circular disc (butterfly) inside a pipeline using compressed air. To control the flow of liquids, gases, or slurries, the disc revolves on a shaft. Pneumatic actuator automation, in contrast to manual valves, allows for quick, remote, and accurate operation, which makes these valves perfect for sectors that need dependability and performance in harsh environments.

Design and Construction

It becomes clearer how a pneumatic operated butterfly valve provides reliable service when one understands its structure:

1. Valve Body

The exterior casing that slides between pipeline flanges or wafer connectors is called the valve body. It is made to be strong, resistant to corrosion, and tightly sealed.

2. Disc

The fluid flow is managed by the central revolving plate, or butterfly. From completely closed (stopping flow) to fully open (allowing flow), the disc rotates 90 degrees.

3. Shaft

The disc and actuator are connected by a sturdy shaft. Smooth rotation and low torque requirements are guaranteed by precision machining.

4. Pneumatic Actuator

The key component that makes automatic operation with compressed air possible is the pneumatic actuator. It transforms air pressure into mechanical torque using the principles of a piston or diaphragm.

5. Seals and Seat

High-performance elastomeric, PTFE, or metallic seats and seals are built into the valve body to stop leaks and ensure tight shut-off.

6. Mounting Kit and Accessories

Limit switches, solenoid valves, positioners, and manual override kits are examples of accessories that improve control and flexibility.

Materials Used

Butterfly valves that are pneumatically operated are designed with longevity and chemical compatibility in mind:

-

Valve Body Materials: Ductile Iron, Carbon Steel, Stainless Steel (304/316), Alloy Steel

-

Disc Materials: Stainless Steel, Aluminum Bronze, Nickel Plated Ductile Iron

-

Seat Materials: EPDM, NBR, PTFE, Viton

-

Shaft Materials: Stainless Steel or High-strength Alloy Steels

Material selection depends on operating conditions, fluid types, temperature, pressure, and industry standards.

Working Principle

The working principle of a pneumatic operated butterfly valve is simple yet effective:

-

Signal Input: A control signal (electrical/PLC command) activates the solenoid valve.

-

Air Supply: Compressed air flows into the actuator chambers.

-

Actuator Movement: Air pressure moves the actuator piston or diaphragm, generating torque.

-

Disc Rotation: The torque rotates the shaft and attached disc.

-

Positioning: The disc aligns either parallel (open) or perpendicular (closed) to flow. Intermediate angles control throttling.

-

Feedback: Positioners and switches send feedback to the control system for precise monitoring.

Pneumatic butterfly valves are perfect for automated systems that need to operate quickly and dependably because of their quick actuation.

Key Advantages

Pneumatic butterfly valves are appropriate for a variety of sectors due to their many benefits:

Fast Operation

Rapid valve open/close operations are made possible by pneumatic systems’ fast actuation speed, which is essential for process control and emergency shut-off applications.

Automation & Remote Control

Remote intelligent control is made possible by integration with DCS/PLC systems, which lowers the need for manual intervention and improves operational safety.

Enhanced Safety

These valves increase process safety, particularly in high-pressure or toxic situations, by reducing human exposure to hazardous zones.

Energy Efficiency

When combined with optimised control systems that minimise needless air usage, pneumatic actuators are particularly energy-efficient.

Leak-Proof Performance

Even in demanding applications, minimal leakage and superior shut-off performance are guaranteed by precision engineering and high-quality seals.

Low Maintenance

These valves have a lower life-cycle cost since they require less maintenance due to their robust structure and fewer moving parts.

Industry-Wise Applications

Butterfly valves with pneumatic operation are very adaptable and used in many different industries:

1. Water & Wastewater Treatment

utilised in filtration, aeration, and effluent discharge systems to control flow. Long-term performance in harsh water treatment conditions is guaranteed by their corrosion-resistant versions.

2. Chemical & Process Industries

Pneumatic butterfly valves use chemical-resistant materials to handle hazardous, corrosive, and high-temperature fluids while maintaining process integrity.

3. Power Generation

With their robust structure and fast actuation, these valves satisfy demanding power plant requirements for everything from steam isolation to cooling water management.

4. Oil & Gas

utilised in upstream, midstream, and downstream pipelines for flow control, batching, and line isolation. They are industrial mainstays due to their resistance to combustible conditions and high pressures..

5. Pharmaceutical Industry

Pneumatic valves facilitate contamination-free operation with clean-friendly designs in hygienic process lines and precise fluid dosing.

6. Food & Beverage

Butterfly valves, which have food-grade seat alternatives, regulate operations in brewing, dairy, beverage, and food handling systems while adhering to hygienic requirements.

7. HVAC Systems

Pneumatic butterfly valves control water and air flows in heating and cooling loops to increase comfort and energy efficiency.

8. Pulp & Paper

These valves provide strong performance in abrasive fluid conditions for controlling pulp stock, chemical additives, and wastewater.

9. Cement Industry

Pneumatic valves are used in slurry control, material handling, and dust-filled air systems. They can operate consistently in harsh conditions.

10. Mining Industry

Rugged pneumatic butterfly valves offer dependability in challenging, abrasive environments in slurry pipelines, tailings transfer, and dewatering systems.

Why Choose MNC VALVES in Ahmedabad?

MNC VALVES, a leading manufacturer of pneumatically powered butterfly valves in Ahmedabad, India, is distinguished by its superior quality, ability to be customised, and complete adherence to industry standards.

Quality Assurance

MNC VALVES produces valves that adhere to API, ANSI, and IS standards by using premium materials and cutting-edge manufacturing techniques.

Customized Solutions

Since there is no one-size-fits-all solution, MNC VALVES provides completely customisable valve configurations that are suited to your process requirements, from material selection to actuator sizing.

Engineering Support

For optimal efficiency, qualified application engineers assist you in choosing, designing, and commissioning the best pneumatic operated butterfly valves.

On-Time Delivery

MNC VALVES guarantees prompt shipping and assistance throughout India and international markets with specialised production planning and logistics.

Contact MNC VALVES – Ahmedabad, India

For industrial-grade pneumatic operated butterfly valves and automation solutions, reach out to:

MNC VALVES

Email: info@mncfvalves.com

Website: www.mncvalves.com

Address: Narol, Ahmedabad – 382405, Gujarat, India