CNC machining is a computer-controlled manufacturing process used to cut, shape, and finish metal and composite materials with high precision. In modern aerospace production, this technology plays a critical role because even the smallest dimensional error can affect safety, performance, and long-term reliability. Manufacturers depend on CNC systems to deliver repeatable accuracy while working with advanced alloys and lightweight materials. Industries such as aerospace, medical devices, and automotive engineering rely on CNC machining to meet strict design and regulatory requirements. For aircraft manufacturing in particular, CNC machining supports the complex geometry and tight tolerances required for airplane frames, ensuring that every component fits correctly within the overall structure and performs as intended throughout the aircraft’s service life.

Understanding CNC Machining in Aerospace Frame Production

CNC Workflow From Digital Design to Finished Airplane Frames

The production of airplane frames using CNC machining begins with detailed digital models created in CAD software, where engineers define geometry, tolerances, and functional requirements. These models are then translated into CAM programs that generate precise toolpaths for machining equipment. The CNC machine follows these instructions to remove material layer by layer, forming Aircraft structural frames with consistent accuracy. This workflow minimizes manual intervention and reduces the risk of variation between parts. In aerospace environments, the ability to trace each step digitally also supports documentation, quality audits, and design revisions, making CNC machining a dependable process for manufacturing Airframe framework components that must meet strict certification standards.

CNC Machine Types Used for Structural Aerospace Parts

Different CNC machines are selected based on the complexity and size of airplane frames. Three-axis machines handle simpler geometries, while four-axis and five-axis systems allow simultaneous movement for complex contours and internal features. CNC turning centers are often used for cylindrical or rotational elements within the Aircraft load-bearing frame structure. The flexibility of modern CNC equipment enables manufacturers to machine multiple features in a single setup, reducing handling errors and improving dimensional consistency. This capability is especially valuable when producing parts that must align precisely during fuselage frame assembly, where even minor misalignment can affect structural integrity.

Precision Requirements for Airplane Frames

Tolerances and Dimensional Control in Aircraft Structures

Precision is fundamental when machining airplane frames because these components distribute loads throughout the aircraft body. Tight tolerances ensure that Aircraft structural frames fit together as designed, maintaining proper stress paths and load transfer. CNC machining allows manufacturers to control dimensions within microns, even when working with challenging materials such as titanium or high-strength aluminum alloys. Consistent dimensional control also supports interchangeability, allowing replacement parts to fit without modification. In aerospace manufacturing, this level of accuracy is essential to ensure that Airframe framework components perform reliably under varying temperatures, pressures, and vibration conditions.

Material Behavior and Structural Reliability

Understanding material behavior is critical when machining parts for the Aircraft load-bearing frame structure. Metals can deform under cutting forces or thermal changes, which must be accounted for during programming and process planning. CNC machining provides the ability to adjust cutting parameters precisely, reducing internal stresses and maintaining material integrity. This controlled approach helps prevent micro-cracks or distortions that could compromise long-term durability. By maintaining consistent machining conditions, manufacturers can produce airplane frames that meet both mechanical performance requirements and fatigue life expectations, supporting safe and reliable aircraft operation.

Manufacturing Considerations for Fuselage Frame Assembly

Cost, Lead Time, and Process Efficiency

Producing airplane frames requires balancing precision with cost and production timelines. CNC machining improves efficiency by reducing manual labor and rework, which directly affects lead times. Automated tool changes and multi-axis machining allow multiple operations to be completed in one cycle, streamlining production. While tighter tolerances may increase machining time, they often reduce downstream assembly issues, ultimately lowering overall manufacturing costs. For aerospace programs with long production runs, CNC machining provides predictable output and repeatable quality, supporting stable planning for fuselage frame assembly and broader aircraft manufacturing schedules.

Quality Control and Inspection Practices

Quality assurance is a critical part of CNC machining for airplane frames. Coordinate measuring machines, laser scanning, and in-process probing are commonly used to verify dimensions and surface quality. These inspection methods ensure that Aircraft structural frames meet design specifications before assembly. Digital inspection records also support traceability, which is essential in regulated industries like aerospace. To better understand how precision machining supports fuselage components, many engineers reference resources such as advanced CNC machining for aerospace fuselage frame production to study real-world manufacturing approaches and quality strategies used in this field.

Applications and Supplier Selection in Aerospace CNC Machining

Aerospace Use Cases for CNC-Machined Frames

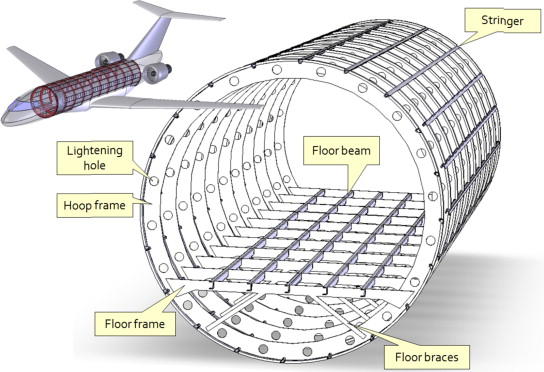

CNC machining is widely used across aerospace applications, from commercial aircraft to defense and space systems. Airplane frames manufactured through CNC processes form the backbone of fuselage sections, supporting internal systems and external loads. These components must integrate seamlessly with skins, stringers, and bulkheads. CNC machining also enables rapid prototyping and low-volume production for new aircraft programs, allowing engineers to validate designs before full-scale manufacturing. The adaptability of CNC systems makes them suitable for evolving aerospace requirements, where design changes are common during development phases.

-

CNC machining supports both prototype and production-scale airplane frames

-

Multi-axis capability enables complex geometries and integrated features

Choosing a CNC Manufacturing Partner for Aerospace Projects

Selecting a CNC machining partner for airplane frames requires careful evaluation of technical capabilities and process control. Manufacturers should demonstrate experience with aerospace materials, quality systems, and inspection standards. Clear communication between design and manufacturing teams is also essential to address tolerances, surface finishes, and assembly requirements. A capable partner will understand the functional role of Aircraft load-bearing frame structure components and align machining strategies accordingly. Long-term collaboration helps ensure consistency across production batches and supports continuous improvement as aircraft designs evolve.

-

Evaluate machining capability, inspection equipment, and material expertise

-

Prioritize suppliers with strong documentation and communication practices

Conclusion

CNC machining has become a foundational technology in the production of airplane frames, supporting the precision, consistency, and reliability required in aerospace manufacturing. By enabling tight tolerances, controlled material behavior, and efficient production workflows, CNC processes help manufacturers meet demanding structural and regulatory requirements. The integration of advanced machines, digital workflows, and rigorous inspection ensures that Aircraft structural frames perform as intended throughout an aircraft’s service life. As aerospace designs continue to evolve, CNC machining will remain a key enabler of safe, efficient, and well-engineered airframe structures, supporting innovation while maintaining the high standards expected in the aviation industry.