Learn how to select the best CCMT boring bar for accurate machining. Understand angles, 12mm CCMT boring bar use, insert selection, and CNC tool compatibility

How to Choose the Right CCMT Boring Bar for Precision Machining

Selecting the right CCMT boring bar is one of the most important decisions for achieving accuracy, stability, and long tool life in internal turning operations. Whether you’re handling fine finishing or deep boring inside a workpiece, the tool you choose directly affects your surface finish, tolerance control, machining efficiency, and overall productivity.

In today’s competitive manufacturing environment, CNC machinists can’t afford trial-and-error when choosing tooling. A well-selected boring bar can eliminate chatter, reduce insert wear, and guarantee precise diameters in every pass. This guide explains how to choose the ideal option—including factors like material, size, overhang, insert geometry, and boring bar angle—to help you achieve the best results.

1. Understand what a CCMT Insert Is Designed For

Before selecting a CCMT boring bar, you must understand what CCMT inserts are. CCMT is a common turning insert shape featuring 80° rhombic geometry, positive rake, and excellent chip control. They are ideal for:

- Steel, alloy steel, and stainless-steel machining

- Finishing and semi-finishing operations

- Low vibration cutting

- Improved chip evacuation

Because of their positive cutting edge, CCMT inserts pair well with smaller-diameter bars like the 12mm ccmt boring bar, especially for jobs requiring precise internal machining.

2. Choose the Right Boring Bar Material

The performance of your internal turning operation highly depends on the material of the boring bar. Options include:

Carbide Boring Bars

- Highest rigidity

- Best for deep boring

- Reduced chatter

- Suitable for high-speed finishing

Carbide bars pair beautifully with CNC tool setups where precision and stability are essential.

Steel Boring Bars

- More flexible than carbide

- Cost-effective

- Suitable for shallow boring or roughing

Anti-Vibration Boring Bars

- Specially engineered for long overhangs

- Excellent stability and finish quality

Choosing the bar material ensures whether your boring bar can handle high speeds, deep cuts, or long internal diameters.

3. Select the Correct Diameter and Length

One of the most common causes of vibration in boring is using a bar too long for its diameter. The rule of thumb is:

Overhang ≤ 6 times the bar diameter

For example:

- A 12mm ccmt boring bar should not exceed 72mm of stick-out for vibration-free performance.

- Carbide bars may allow slightly higher values because of their density and stiffness.

A properly selected diameter improves accuracy and prevents deflection, ensuring your internal surfaces are smooth and consistent.

4. Pay Close Attention to the CCMT Boring Bar Angle

The ccmt boring bar angle plays a major role in determining how your tool interacts with the workpiece. This angle, often referred to as the lead angle or approach angle, impacts:

- Chip flow direction

- Cutting force distribution

- Surface finish

- Tool life

For general internal turning, 95° approach bars are most common. However, depending on the bore geometry or clearance needed, other angles may be required. Choosing the wrong angle can result in rubbing, excessive insert wear, or poor finish.

A good CCMT boring bar should provide enough clearance inside the workpiece while maintaining optimal cutting engagement.

5. Match the Insert Geometry to Your Application

CCMT inserts come with different chip breakers and nose radii. For example:

Nose Radius Selection

- Small radius (0.2–0.4 mm): Best for finishing

- Larger radius (0.6 mm+): Suitable for semi-finishing or roughing

Chip Breakers

Choose based on material and depth of cut. Some chip breakers are designed for smooth finishing cuts, while others handle heavy loads.

Pairing the correct insert characteristics with the right bar ensures your boring bar delivers unbeatable accuracy.

6. Check Coolant Capabilities

Internal machining generates heat quickly. A CNC tool setup benefits immensely from a boring bar with internal coolant delivery. This improves:

- Chip evacuation

- Insert cooling

- Surface finish

- Tool life

Coolant-through bars are especially effective for deep or narrow bores where chips may clog.

7. Evaluate Your Machine and Setup Requirements

Every machine has its own specifications and limitations. Before selecting the right bar, consider:

- Tool holding system (VDI, HSK, BT, etc.)

- Maximum spindle speed

- Turret size

- Stability of your work-holding

- Material of the workpiece

For precision machining, ensuring compatibility between the machine and tooling setup guarantees reliable results and extended tooling life.

8. Prioritize Rigidity for Better Surface Finish

The last thing any machinist wants is chatter marks or inconsistent bore diameters. Rigidity is the most important factor in internal machining. A rigid boring bar will minimize vibration, improve cutting accuracy, and deliver flawless surface finish.

Selecting a carbide or anti-vibration bar becomes crucial when boring deep holes, machining hard materials, or running high RPM operations.

FAQs

- What is a CCMT boring bar used for?

It is used for internal turning, boring, and finishing applications using CCMT inserts, providing precision and good chip control.

- Is a carbide boring bar better than steel?

Yes, carbide offers higher rigidity, making it ideal for long overhangs and precision internal machining.

- What size CCMT boring bar is best for general machining?

A 12mm ccmt boring bar is widely used because it fits many CNC lathes and offers a good balance of strength and versatility.

- Why does the ccmt boring bar angle matter?

It determines clearance, chip direction, and cutting engagement. The wrong angle can cause rubbing or vibration.

- Can CCMT inserts be used for both roughing and finishing?

Yes, depending on the chip breaker and nose radius selected, CCMT inserts can handle both operations effectively.

Conclusion

Choosing the right CCMT boring bar involves balancing material selection, size, angle, insert geometry, and machine compatibility. When selected correctly, it delivers exceptional accuracy, long tool life, and superior internal surface finishes.

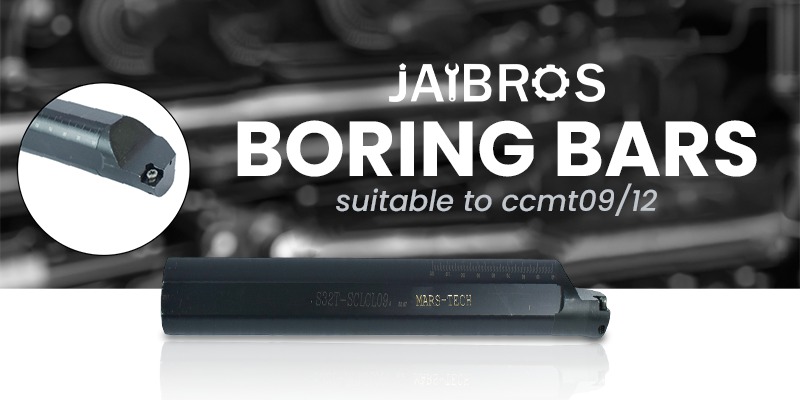

At Jaibros, we specialize in premium CNC tooling solutions, including boring bars, inserts, and high-performance accessories. Our products are known for durability, precision, and consistent performance—trusted by machinists across industries.